A 'SALT WATER' POOL

CHLORINE PRODUCTION IN YOUR HOME SWIMMING POOL

BY 12 VOLT

ELECTROLYSIS OF COMMON SALT

A NEW ZEALAND INVENTION THAT HAS SWEPT THE WORLD!

Cascade introduced Salt Water chlorination devices in 1972

By Laurence E Ogden - NZMPB Diploma Pool Technology

WHEN DID IT ALL START?

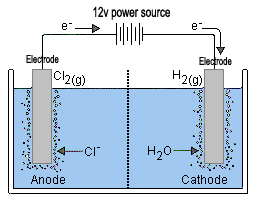

In October 1972, for the Southern Hemisphere 'Summer of 1973', Cascade introduced its locally designed and manufactured Aquatech IG450 Salt Chlorinator to the wordl market- a device which created Sodium hypochlorite (liquid Chlorine ) from a 2% (20,000 ppm) salted pool water by passing the water through a 1-1/2" (40mm) clear PVC tube encasing a 12 volt DC multi-plate stainless-steel-mesh electrode as part of the filtration system's 'return-to-pool' line.

SOLD FOR $695 IN 1973!!

When small 14' x 28' family pools were selling for less than $1,995.00 installed, this was expensive (!) - but proved to be a great improvement over the huge $250 "one hundred pound" (35 Kg) drums of granular HTH pool chlorine powder we included with Cascade pools in those days.

At that time in New Zealand it was illegal to repack powder chlorine (aka Granular Chlorine) into smaller packs, and the HTH brand granular chlorine could not even be stocked in drums or sold without a Dangerous Goods license, so customers had to take the full size drum. This was a problem to keep tightly sealed, and the chloirine gas emmitted when the lid was constantly being removed was extremely hazardous.

.jpg) The IG450 - a World First?

The IG450 - a World First?

The initial model IG450 was developed by Cascade Pools New Zealand's founder Larry Ogden from an idea he had been thinking about since the mid 1960's and intended for 10,000 gallon pools - the average size home pool - hence the name '450' ( 45,000 litres) and IG stood for In Ground, as it was intended for in-ground swimming pools.

The IG450 units had stainless steel four-plate electrodes - which eroded within two to three years, and $250 to replace was a high cost in those days. Later models (the IG450P) used a Platinum electro-plated stainless steel electrode which lasted two to three times as long (but cost twice as much to replace)

In 1974 we introduced polarity switching (I think it used a HEXFET - and Metal Oxide Sintered Field Effect Transistor MOSFET but that may have been later in the production run) which reversed the DC + 'Positive' and - 'Negative' (DC) current every minute or so. Reversing the polarity dumped the accumulated gunk off the electrode giving the "appearance" of an extended service cycle between acid washes, and was sold as "Self Cleaning" (continuing to this day) but of course the dumped gunk soon reattached itself!

The polarity reversing idea seemed good at the time, but unfortunately the cell gradually continued to build up a thin coating of calcium "from shock dosing periodically with Cal Hypo - which inhibited the production of chlorine, so they still had to be periodically dismantled and given a bath in dilute hydrochloric acid to "freshen" them up. The polarity switching is still being used by Salty manufacturers today, but as stated it is a short term solution to the problem of calcium buildup and gradual deterioration of the electrode.

Sodium Hydroxide (aka Caustic Soda - commonly known as DRAINO drain unclogger)

It wasn't until many years later (1994, in fact) that we fully appreciated the chemistry the pool water. After all, the pools 'never went green' and everybody was happy!

Unfortunately, the old saying 'no free lunches' came true. We were 'structural engingeers' NOT chemical engineers!

We had overlooked the production of sodium hydroxide (Caustic Soda NaOH) - being equal in quantity with the sodium hypochlorite production - and as a consequence, the pool pH was always extremely high. as the pH of Caustic Soda tops out at 14 (on a scale of 0 - 14) and Sodium Hypochlorite has a pH of 11.0 - 13.0

The pool pH rose so high, in fact, that the sterilisation of the pool is in jeopardy, as once the pH exceeds 8.0 there is literally no effective sanitisation taking place, and the pools were constituting a health & safety risk to the users if the pool owner was unaware of - and did not take action to reduce - the high pH situation! Dosing the pool with gallons of Hydrochloric Acid became a necessary and regular task!

.jpg)

Our final version IG450A incorporated an acid pump to remedy this situation, but the unit cost soared to $2,800.00 plus the cost of the 40 litre drum of hydrochloric acid which was inconveniently located adjacent to the pool filtration.

The presence of such large quantities of dangerous acid also posed a questionable risk to children who might have access to the filtration area.

After 21 years of using 'Saltys' we abandoned the idea!

Seeing this as an extreme safety hazard for young - and curious - children, in 1994 we discontinued the installation of salt chlorinators in favour of the US made Aquagenie Skimmer/Feeder system - which we still use today in conjunction with an activated oxygen generrator (Ozone or O3).

Other problems we encountered with salt water pools includes premature corrosion of pool equipment and pool surrounds, the need to top up with heavy 25kg bags of salt as rainfall dilutes the pool water, and the need to periodically acid wash the electrode to remove calcium coating which reduces the performance of the unit.

Voltage Leakage: The issue of "voltage leakage: was a major problem in the early days, as the "stray voltage" in the pool water tended to destroy the pool pump and pool heater internals in a short time! Oh ... and the danger to pool users if they "shorted" to earth while in the pool (i.e. don't grab anything "Earthed" outside of the pool - such as a stainless steel pool ladder - while standing in the pool)! Swimmers with PaceMakers (Heart monitors) were deemed to be at risk, according to one medical advisor, but I had no feedback on the accuracy of this warning.

Cascade circumvented the voltage leakage problem to a large degree by installing an earth strap from the pool ladder to an earthing rod. In later years, as stainless steel pool ladders went out of fashion in favour of internal "walk in" steps, we started installing bi-metal earth plate internally in the pool skimmer connected to an earth wire and earthed to the steel pool frame. We continue with this practise to this day - even though we don't generally fit saline chlorinators to our pools any more - in favour of passive Ozone - we include the earth strap wire in case our customer retrofits a "Salty" at some later stage! We don't want our pools to constitute a hazard even if we were not directly responsible!

My 'Salt Chlorinator' idea was taken to the USA in 1973:

I took two UL approved sample units to the U.S.A. (1973 Chicago Trade Fair (?) Illinois, USA) where great interest was shown in them - in fact my sample IG450s both 'went missing' on that trip - but the following year I returned to see a proliferation of similar units to the IG450 - even ones painted bright Yellow like ours - being manufactured in such diverse places as South Africa, Mexico and Australia.

SUMMARY: In the period 1965 to 1971, I had spent nearly 6 years involved in the residential swimming pool industry in the USA, United Kingdom and Europe, and had never seen any pool device available on the market like a Salt Chlorinator during this time.

I have been unable to find evidence of any use of such a device prior to my introduction onto the market of the IG450 - although I have heard anecdotal stories of similar developments in Australia around that time, but nothing that was on the home or overseas pool industry market - so I assume that in 1972 'Larry Ogden and Cascade Pools New Zealand were thecommercial originators of residential Salt Water Pools Chlorinators.

I would be interested to hear if this is not so - but at least I do know that I had never seen anything like my product in the major home pool markets of the late 'sixties during my years over there.

In 1972 I had investigated obtaining a World Patent, but the cost (quoted at $US 33,000 - the $NZ was par at that time) was too much for a young 31 year old to come up with - especially as I had recently purchased a three-bedroom house on a half-acre in a nice Auckland suburb for $NZ 16,500. After I saw similarities to my Chlorinemaker IG450 from Mexico, the US and other countries on the US market I subsequently learned from the Patent Attorneys that the World Patent would have meant fighting a Patent case personally in each of the countries that were making similar devices - so it would have been beyond my resources to do so! They didn't bother to advise me of this detail previously ("You want Legal Advice? We are the Patent Office... Legal is the next door up the corridor") - but I guess that's lawyers for you!

Why don't we use saline chlorinators today?

In our opinion our combined Aquagenie+Ozone system is far better, cheaper to operate and more reliable at sterilizing pathogens & bacteria in the swimming pool -making your pool safer for your children.

And after all - isn't that the whole idea?

Click the graphic at left for more information on the Aquagene+Ozone system

Without Prejudice E&OE (C) 2002

Updated and Checked for veracity June 2020